Laundry Business Consulting

Equipment Analysis Case

What is Equipment Analysis?

We can help you make the best decision for the business, by offering various criteria such as cost, specification, features and customer service

An Analysis Case

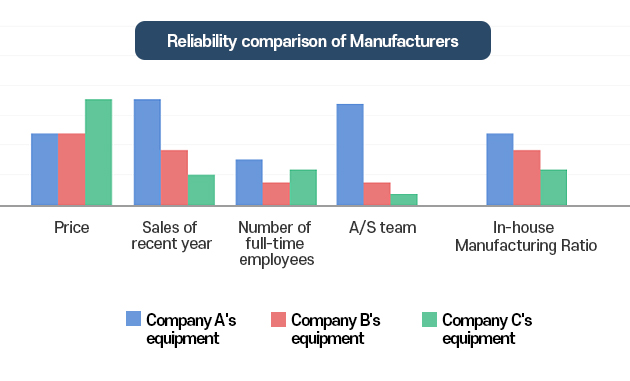

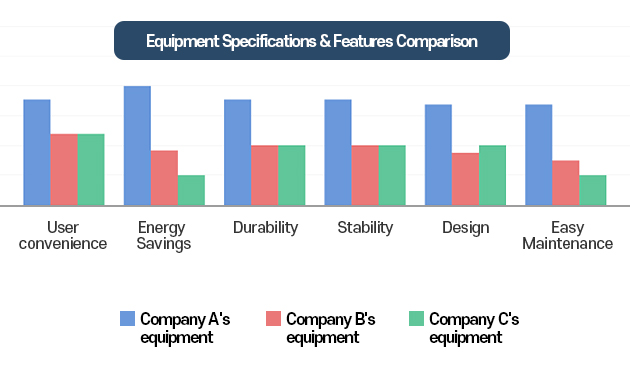

1) Comparative Analysis of Washing Machines

- A customer wants to add a 50kg washing machine in the business. We offer comparative analysis of 3 different manufacturers in terms of Manufacturer, Eqiupment Performance and Endurance, and Customer service.

View detailed comparison Analysis tables

| sort | Company A's equipment | Company B’s equipment | Company C's equipment | ||

|---|---|---|---|---|---|

| price | Deluxe spec | 20 million won($ 15,300) | - | - | |

| General spec | 18 million won($ 13,800) | 18 million won($ 13,800) | 16 million won($ 12,300) | ||

| Manufacturer Comparison | |||||

| Sales of previous year | 8 billion won($ 6.14M) | 3.5 billion won($ 2.68M) | 1.7 billion won($ 1.30M) | ||

| Number of full-time workers (persons) | 30 | 15 | 8 | ||

| A/S personnel (persons) | 5 | 1 | 1 | ||

| Manufacturing plant site (㎡) | 5950 | 165 | 330 | ||

| In-house manufacturing Ratio | 60% | 40% | 20% | ||

| Location | DaeGu | DaeGu | GyeongGi-Do | ||

| specification Comparison | |||||

| Processing capacity (kg/cycle) | 50kg | ||||

| Drum | |||||

| Volume(ℓ) | 480 | 470 | 455 | ||

| Diameter(mm) | 970 | 1000 | 1000 | ||

| Depth(mm) | 650 | 600 | 580 | ||

| Shock Relief Device |

|

|

|

||

| Programs & Operation panel | Up to 10 programs, Touch Screen |

Up to 4 programs, Buttoned control panel |

Up to 4 programs, Buttoned control panel |

||

| Rotation | |||||

| Washing | 20~55RPM / Freely adjustable | Three level speed adjustment : low/medium/high | Five level speed adjustment : 1 to 5 | ||

| Extraction | 200~790RPM / Freely adjustable | Three level speed adjustment : low/medium/high | Five level speed adjustment : 1 to 5 | ||

| Water temperature control | Washing/Rinsing Custom temperature settings are available |

||||

| Water level control | 12-level adjustable | 3-level adjustable | 3-level adjustable | ||

| Appearance size(WxDxH) | mm | 1500x1550x1750 | 1520x1560x1800 | 1555x1375x1825 | |

| Electrical specifications | V/Hz | 3P 380V, 60Hz | 3P 380V, 60Hz | 3P 380V, 60Hz | |

| Power consumption | kW/H | 7.5kW | 7.5kW | 7.5kW | |

| Weight | kg | 1,550 | 1,580 | 1,350 | |

| Major part Comparison | |||||

| Bearing | Japanese/Korean | Korean | Korean | ||

| Motor | Hyundai Heavy Industries Co. Ltd | Hyundai Motor Co., Ltd | Chinese Motor | ||

| Inverter | Korean LS-electric | Chinese DELTA | Chinese DELTA | ||

| Water supply valve | Parker Corporation, USA | Korean HyoSin Valve | Korean HyoSin Valve | ||

| Inner/outer drum material | STS/STS | STS/SS41 | STS/SS41 | ||

| Control Method | PLC Control | Relay method | Relay method | ||

| SUMMARY | |||||

| Program |

|

|

|||

| Maintenance | 20 Agencies nationwide | Handled directly from HQ | Handled directly by manufacturer | ||

| Energy saving |

|

|

|||

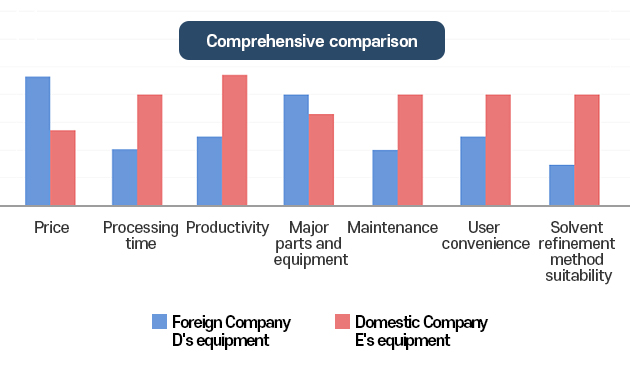

2) Comparative Analysis of Dry Cleaning Devices

- A customer using a machine from over-sea manufacturer. Happy with the performance, but problems with customer service cause loss in productivity. Asked for a machine with same performance and better customer service.

View Detailed Comparison Analysis Tables

| Sort | Expected purchase Foreign Equipment D |

Similar Specifications Domestic Equipment E |

Remark |

|---|---|---|---|

| Country of Manufacturing |

Italy | Domestic Manufacturing/Sales |

For Company D’s Equipment,

|

| Distributor | Domestic Company | ||

| Appearance index | 2704x2090x2500 | 2000x1600x2200 | - |

| Processing capacity | 32kg | 25kg | - |

| Program & Operation panel |

|

|

Equipment of D Company

Equipment of E Company

|

| Processing time per 1 cycle | 70 to 80 minutes | 45 minutes |

Washing-extraction-drying-solvent recovery : 1 cycle Equipment E |

| Mount Type |

|

|

|

| Solvent Refining method | Distillation method | Double filter Refining method |

Both D and E use hydrocarbon solvent. Distillation is not suitable for hydrocarbon solvent because composition changes when heated, causing bad smell. |

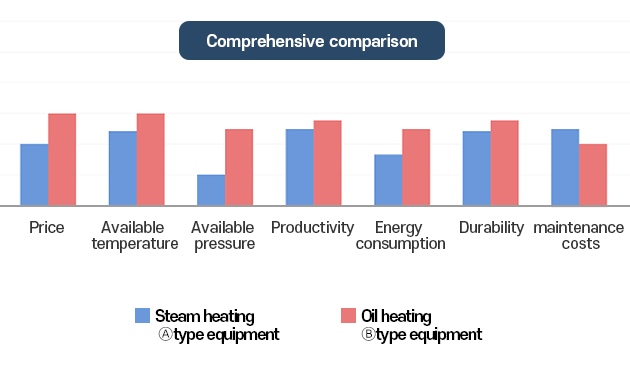

3) Comparative Analysis of Roller Ironer Equipment

- A customer wants to buy a roller ironer from a certain manufacturer. We offered analysis among different types of heating methods to figure out the best type for the customer's case.

View Detailed Comparison Analysis Tables

| Same Manufacture Steam Heating Roller Ironerⓐ |

Same Manufacture Oil Heating Roller Ironerⓑ |

Remark | |

|---|---|---|---|

| Purchase price | 150% of ⓐ |

ⓑtype is 50% to 60% more expensive when compared to ⓐtype.

*May vary by manufacturers. |

|

| Available Temperature | 170°C | 225°C | |

| Pressure of use | 6-7bar | 2bar | ⓑtype can perform with lower pressure. |

| ROLL Diameter | Ø1200 | Ø1200 | |

| ROLL QTY | 2EA | 2EA | |

| Heating Method | Steam Method | GAS HEATING OIL CIRCULATION SYSTEM | |

| Processing Ability |

|

|

Based on 3,000mm sheet |

| Heat consumption | 400,000Kcal | 250,000Kcal |

|

| Durability / pros and cons |

|

|

|

| SUMMARY | Efficiency |

|

|

| Stability | · ⓑType Equipment can work reliably at lower pressure than ⓐtype Equipment | ||

| Consumption of calories | · When ironing and drying the same laundry, ⓑType equipment can work with less heat than ⓐtype equipment | ||

| · Reduced energy consumption - Reduce operational/maintenance costs | |||

| Durability and Maintenance Costs | · When used properly, both ⓐ and ⓑ can be used for about 20 to 25 years. | ||

|

|||

|

|||