Smart Laundry

Smart Laundry

SMART LAUNDRY BUSINESS is a digital automation solution that reduces distribution channels between consumers and producers. It allows the entire laundry process to be as automated and standardized as possible to provide more organized and convenient laundry services.

SMART LAUNDRY BUSINESS, proposed by SN, minimizes manual labor in the entire process from warehousing to sorting, washing and packaging, storage, and shipping. The goal is to improve laundry quality and reduce fixed costs, track laundry process status, and record associated data to use for various business purposes.

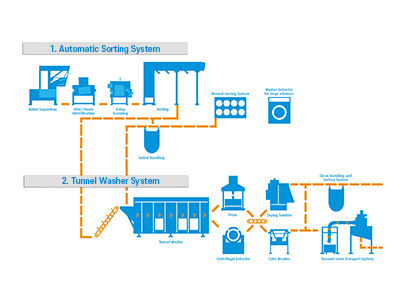

When the laundry is poured into the input conveyor, the robotic arms separate the laundry into single pieces.

The next step is the camera and X-ray. The camera recognizes the fabric type, color, and RFID tag of the laundry, and the X-Ray measures the weight of the laundry and filters out the laundry found with foreign substances.

After passing this process, the laundry is automatically transfered by a conveyor, which can sort the laundry into about 20 categories. The collection box filled with the target weight can be automatically sent to the washing machine.

Unlike stand-alone washer/dryer, it is a laundry system that automatically proceeds and performs the laundry process: Put in → Washing → Extraction → Transfer → Drying

Mainly suitable for washing large linens such as sheets, duvet covers, towels, table clothes, etc.

Continuous Washing Machine System of "JENSEN GROUP" can be applied to clothes washing such as patient clothes and work clothes through program setting. And thanks to self-developed technology, white laundry can be washed together with colored ones.

TUNNEL WASHER SYSTEM - SMART LAUNDRY SYSTEM allows large-capacity laundry to be processed NON-STOP, with the least number of people.

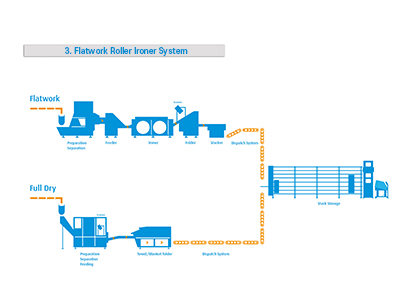

“FLATWORK ROLLER IRONER SYSTEM automatically performs [Input – Drying & Ironing – Folding – Stacking] for large laundry (mainly sheets, duvet covers, table clothes, etc.).

For hotel bed sheets or duvet covers that are difficult to iron and fold manually, "Flatwork Roller Ironer System" can not only speed up work, but also improve ironing quality and reduce worker fatigue.

Flatwork Roller Ironer System is the best for large-scale laundry ironing.

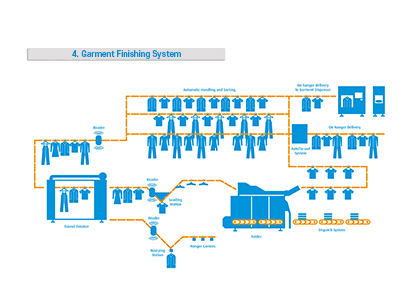

Garments that are not suitable for tunnel washing system should go through different cleaning process. Distribution Conveyor makes this process more convenient.

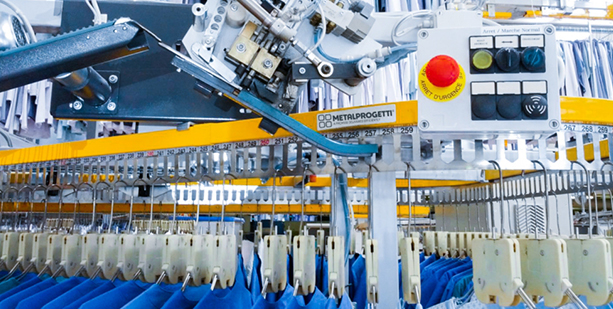

After washing and drying, the laundry gets transferred to the pressing area via the "Distribution Conveyor". Each operator stands in his work spot, gets the clothes being transferred, irons them, then hangs garments on the conveyor again to transport them to send.

In the case of clothes that cannot be tumble-dried or ironed, drying and wrinkle removal can be performed with hot air & steam sprayed through the TUNNEL FINISHER SYSTEM while hanging on a hanger through the rail.

After ironing and finishing, the laundry is transferred to the Assembly conveyor.

For laundry arriving at Assembly Conveyor, the operator enters bar code or label into the system and puts it back on to the conveyor.

When all laundry from a particular customer arrives on to the conveyor, a certain amount of laundry set according to the type or thickness of the clothes gets transferred and packed for packaging.

Packed laundry will be stored in the Storage Conveyor or re-classified and shipped through the Dispatch Conveyor depending on the delivery area.

With 24 hour service automated kiosk, you can pick up / drop off laundry without any face-to-face contact.

Drop off : You can drop off your laundry even when the store is closed, using ID number, card, or QR code.

Pick up : Once you enter your ID data, the system will find your item from the storage and take it to the door.